85-91 Ford F-350 4x4 2" Front Shackle Reversal (OBS Spring)

85-91 Ford F-350 4x4 2" Front Shackle Reversal (OBS Spring)

SKU:FORD-FSROB-002PN-NoPanHard-2WD

Couldn't load pickup availability

Description:

-

Kit provides much better ride than stock by moving shackle to rear of spring

-

Eliminates the weak front shackle design

- Levels truck by lifting 2" and allows use of 35's

-

NEW OPTION! 2wd -> 4wd frame plates. Put a Dana 60 in your 2wd! - This kit is designed for 4x4 trucks. Additional parts are necessary for a 2wd truck. The 2wd frame plates are designed to make mounting the spring hanger easier. There are no jigs available, so it will require measuring to properly locate.

Application:

-

Truck: 85-91 F350 / F250

-

*NOTE* Can be used on 80-91 F150/250/350 Bronco to swap in a solid axle. Bronco/F150 use 2wd kit. No instructions of install

- 80-84 F250/F350 Frame is the same, suspension is different. No instructions of install

-

*NOTE* Can be used on 80-91 F150/250/350 Bronco to swap in a solid axle. Bronco/F150 use 2wd kit. No instructions of install

- Springs: 52" 80-97 Ford F-350 front leaf springs

-

Axle: 85-97 F350 Dana 60 or F250 Dana 50 with Sky's TTB drop Brackets.

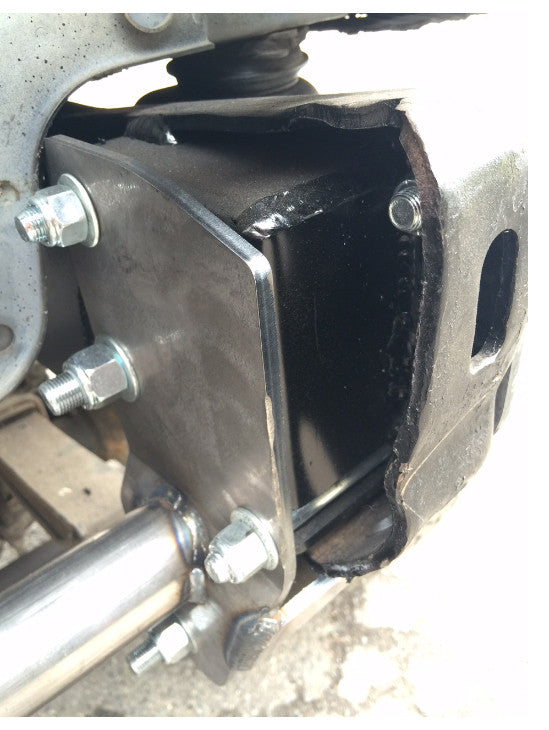

Included:

1 - Front Hanger

4 - 1/2" x 20 x 4.5" Bolts - Flat Washers - Nylocks (Frame)

2 - 1/2" x 20 x 1.5" Bolts - Flat Washers - Nylocks (Frame)

2 - 5/8" x 20 x 4.5" Bolts - Flat Washers - Nylocks (Frame)

2 - 9/16" x 18 x 5.5" Bolts - Flat Washers - Nylocks (Spring)

2 - Inner Frame Plates (weld-on) NOT POWDER COATED

2 - Shouldered Frame Sleeve

2 - Shackles

2 - 9/16" x 18 x 5" Bolts - Flat Washers - Nylocks (Spring)

4 - Bushing halves

2 - Frame Sleeves

Additional Information:

Check out Diesel World's Project Obsessed running Sky's FSR (RSK) Kit

Recommended Parts to Accompany Your Shackle Reversal

The following parts list are intended for those needing help with finding the right parts to accompany their shackle reversal. These parts lists are intended for Stock F-350 85-97 52” (2 leaf) factory springs that are not clapped out with sagged bushings. The kit possibilities are endless when you start coupling a leveling or lift spring to a shackle reversal, we wrote these lists below as a guideline.

If you have specific questions and want an emailed recommended list to suit your specific needs please email us at:

2” Shackle Reversal:

85-91 F-350 - 85-97 Dana 60 - Leveling Purposes – Stock 85-97 F-350 Front Springs:

- 10” Bilstein Shocks (You will need longer shocks for the front, same size if you want to purchase new shocks for the rear as well)

- Adjustable Panhard Bar (keeps axle centered under truck, factory bar is not adjustable and bushings are usually worn out which can create loose steering feeling or death wobble)

- Sway Bar End Link Extensions

85-91 TTB F-250 – Leveling Purposes – Stock 85-97 F-250 Front Springs

- 10” Bilstein Shocks (You will need these longer shocks for the front, same size if you want to purchase new shocks for the rear as well)

- TTB DROP BRACKETS

85-91 2wd-4wd Swap - 85-97 Dana 60 – Stock 85-97 F-350 Front Springs

- 10” Bilstein Shocks (You will need longer shocks for the front, same size if you want to purchase new shocks for the rear as well)

- Adjustable Panhard Bar (keeps axle centered under truck, factory bar is not adjustable to correct length, and bushings are usually worn out which can create loose steering feeling or death wobble)

- Extended Brake Lines

- Lo-Pro Shackle Hangers (for use with 2” kits only)

- F-350 4x4 Stock Pitman Arm (needed to retain full steering on a solid axle)

- Stock Panhard Bracket

- Sway Bar End Link Extensions

- Sway Bar Frame Brackets

Instructions:

This is an instruction for a Super Duty length spring. Simply use 51.5 instead of 55.5 for your spring length.

Installation Notes:

Check out this great install write up on the bullnose forum https://www.garysgaragemahal.com/#nabble-td34173

Sway bar will need to be deleted, or will need end links extended. Our 3" Sway bar end link extensions are available here: 85-97 F-350 Sway Bar End Link Extensions

We have had a few customers with worn out spring bushings and sliders have issues with clearing the shackles on the 2" FSR kits with the military wrap. You need quality to spec parts to make this work.

Instructions for Replacing Leaf Spring Bushings and Isolators

It is common for the front frame horns to be spread due to age as the only thing holding the front of the frame together is the rivets at the engine cross member. You may need to pull the frame together to get the hanger on.

These trucks were not built to a high level of precision. Some of the rivet holes may need to be opened up with a die grinder as the holes may not line up perfectly.

When installing this kit with lift springs, the springs are often shorter than stock as they are re-arched stock springs to get more lift. We recommend drilling just one hole for the spring hanger and holding it in place with one bolt until you are able to set it down and check to see that the shackle angle is satisfactory. Then drill the remaining holes.

Share