Dana 60 King Pin Double Shear Steering Kit for Chevy and Ford Axles

Dana 60 King Pin Double Shear Steering Kit for Chevy and Ford Axles

SKU:DANA-60DSKR-001-FORD

Couldn't load pickup availability

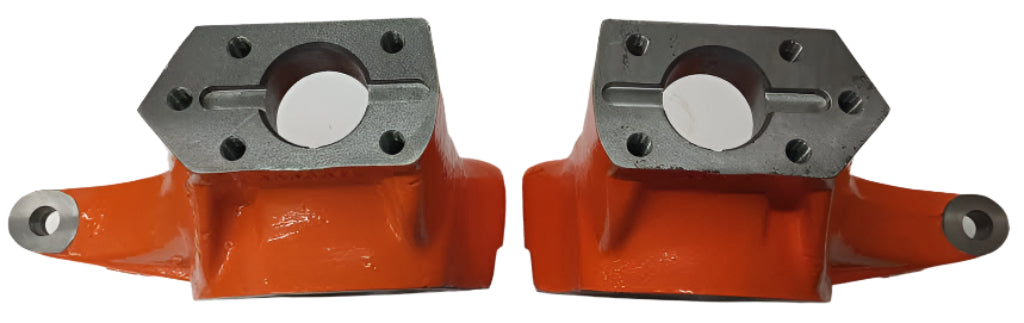

This kit includes Sky's Dana 60 king pin double shear arms and Reid racing steering knuckles featuring a key way interlock system. While we have never seen a 5-stud knuckle with a double shear 3/4 bolt fail, we wanted to go the extra mile for durability.

Our system features two of Sky's double shear springless Dana 60 steering arms, 10 chromoly studs, two 3/4" grade 8 bolts, and 2 Reid knuckles, all keyed for long-lasting performance.

This kit is designed for full hydraulic steering, but can be customized for traditional linkage steering upon request. Our extensive experience with Reid knuckles and our A572 steering arms leads us to believe that this will be your final steering kit purchase!

Some words on our steering arms...

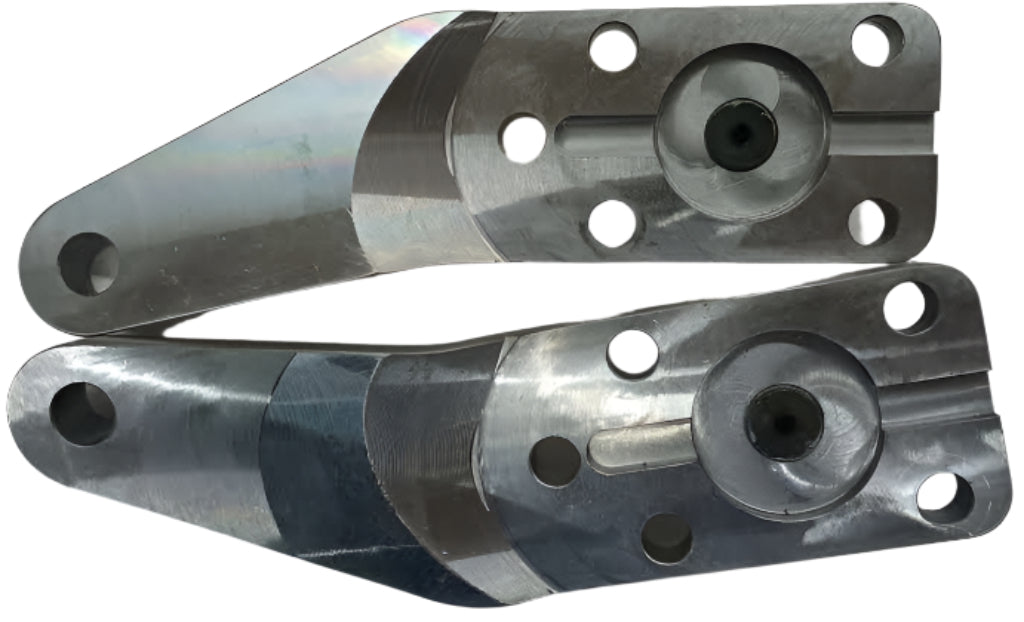

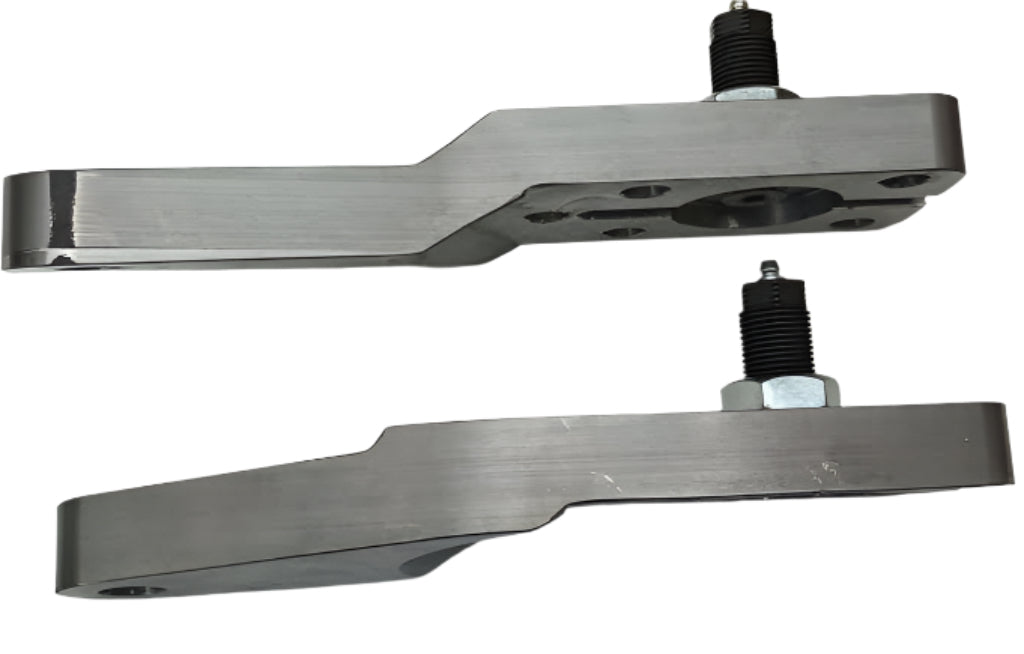

Dana 60 Kingpin Axle Double Shear Hydraulic Steering Arms

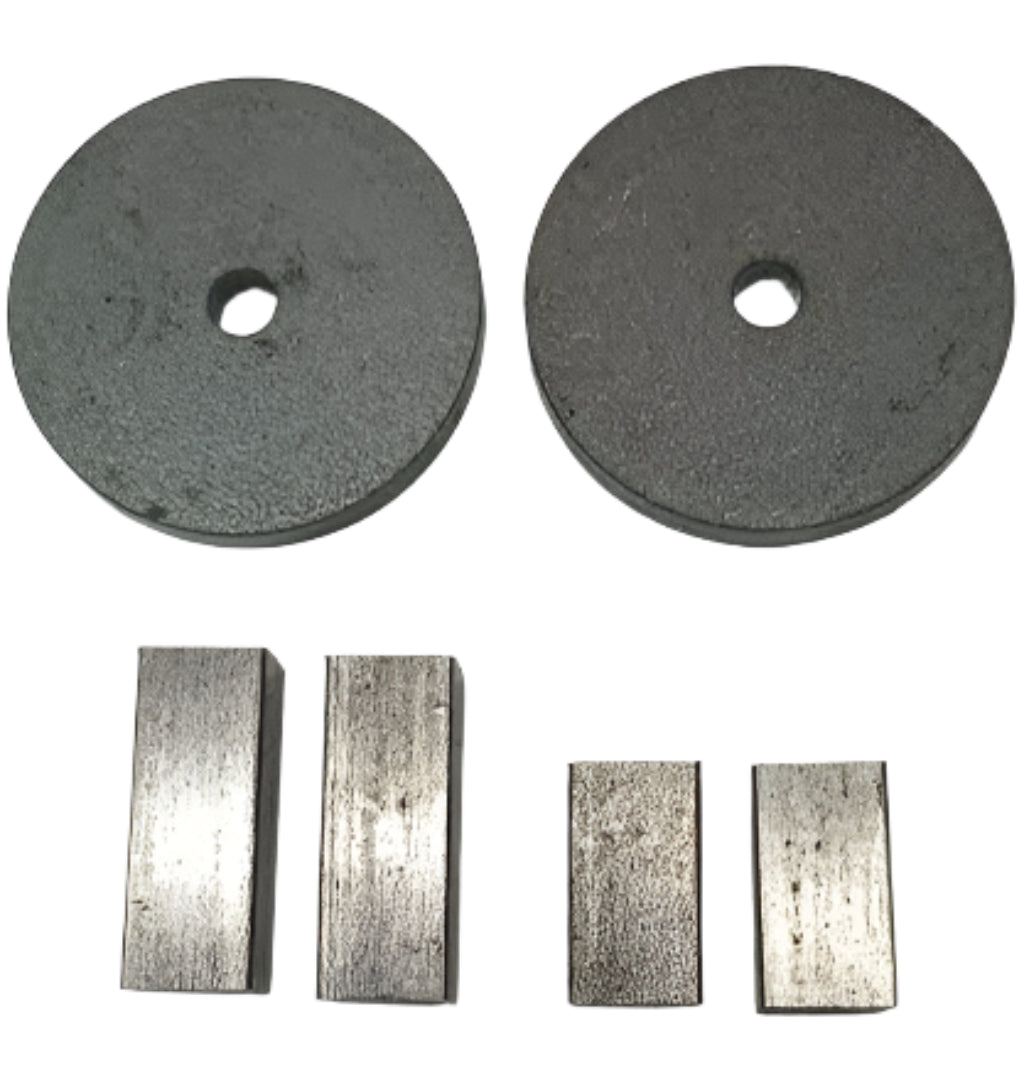

Springless kingpin preload design. Preload adjuster and king pin bushing wear plate included.

5-stud design to work with stock knuckles, Reid Racing knuckles as well as most other aftermarket knuckles.

These arms will fit Reid Racing Ford Dana 60 knuckles, part # D6001F

PLEASE NOTE: These arms will not fit factory Ford knuckles

Arms use tapered nuts to add resistance to side shear.

The design of the arms enables direct alignment with the lower tie rod location, allowing the installer to sandwich the rod end joint between the upper and lower bolt retaining points, effectively creating a double shear.

To accommodate various wheel and tire combinations, the outer steering arm bolt hole has been lowered and brought closer to the tie rod position.

These arms can also be used for non double shear applications and feature built-in camber correction to ensure a flat alignment with the axle.

This steering kit is specifically designed to accommodate an 8 inch stroke ram. To ensure proper fit, the arms will need to be machined to the desired size of the rod end in the lower tie rod hole. Each arm comes with a 3/4 pilot and utilizes factory length studs.

Installation:

Setting kingpin preload:

Lift the bottom of the knuckle so that it is snug, but not lifting the axle. Next, remove the cap, spring, and plastic bushing. Then, install either the bronze or the plastic bushing (if bronze is not available). Clean the mating surface of the knuckle and install studs. Place the preload washer on top of the bushing and install the arm on the studs. Thread the set screw into the arm until it seats on the preload washer. Finally, torque it to 15-20 ft-lbs and lower the jack. Adjust the arm as needed.

When setting up the Dana 60 King Pin Double Shear Steering Kit, begin with a preload torque of 20 ft-lbs to match the stock spring's supplied torque. Turn the knuckle from lock to lock by hand with the steering links disconnected. If there is any vertical play, adjust the set screw accordingly. For a desired kingpin preload, compare both sides and adjust in 1/4 turn increments until satisfied. Finally, secure the set screw using the large nut.

Steering Arm Info:

Our steering arms are now made from ASTM A572 Grade 50 steel, greatly increasing their strength and rigidity. This type of steel is widely used in various applications due to its impressive strength to weight ratio. In fact, it is considered a "workhorse" grade and is commonly found in structural applications, heavy construction equipment, and building structures.

With its exceptional strength capabilities, Grade 50 is a reliable choice for riveted or bolted applications, as well as boom sections, anchoring systems, and other high-stress applications.

Share